Choosing the Right Process: CNC Machining vs Sheet Metal Fabrication for Custom Metal Parts

When it comes to creating custom metal parts, understanding the difference between CNC machining and sheet metal fabrication is crucial. Both processes offer unique advantages, but choosing the right method depends on your specific needs. Whether you’re working on a prototype or a production part, knowing when to use CNC machines or opt for sheet metal fabrication can make all the difference in achieving optimal results.

Quality is never an accident; it is always the result of intelligent effort, said John Ruskin, and this sentiment rings particularly true in the realm of custom metal part production. As industries continue to evolve, the demand for precision and efficiency in manufacturing processes has never been greater. Understanding the nuances between CNC machining and sheet metal fabrication is essential for anyone looking to optimize their production strategy. Each method offers distinct advantages, whether it’s the intricate detail achievable with CNC machines or the versatility of sheet metal fabrication. This article will guide you through the critical differences and considerations, helping you make informed decisions tailored to your specific project requirements. By exploring the various CNC processes and the types of machines available, you’ll gain valuable insights into selecting the most suitable approach for your custom metal parts, ensuring both quality and efficiency in your manufacturing endeavors.

Understanding the difference between CNC machining and sheet metal fabrication

In the realm of custom metal part production, choosing the right manufacturing process is pivotal for achieving both precision and efficiency. While both CNC machining and sheet metal fabrication offer unique advantages, the decision often hinges on the specific requirements of your project. CNC machining is a subtractive manufacturing process that excels in creating intricate and detailed components, making it ideal for producing complex geometries with high precision. On the other hand, sheet metal fabrication generally involves bending, cutting, and assembling metal sheets, offering versatility and cost-effectiveness for larger, simpler parts. Understanding the difference between CNC machining and sheet metal fabrication, as well as the capabilities of each, allows you to make informed decisions tailored to your needs. Whether you’re considering computer numerical control machining for its precision or sheet metal fabrication for its adaptability, knowing when to use each process is crucial for optimizing your production strategy.

2. Selecting the right cnc machining process for your custom parts

When it comes to selecting the right CNC machining process for your custom parts, understanding the specific requirements of your project is paramount. CNC machining offers a range of techniques, each suited to different applications and materials. For instance, if your project demands high precision and intricate details, machining is ideal for producing components with tight tolerances. On the other hand, if you’re working with larger parts or require a faster turnaround, certain types of CNC processes may be more suitable. It’s crucial to evaluate the material properties, desired finish, and complexity of the design to choose the right process that aligns with your objectives. By doing so, you ensure that your custom parts meet the highest standards of quality and performance.

Choosing between CNC machining and other manufacturing methods can be challenging, but focusing on the specific benefits of CNC can guide your decision. Machining involves precise cutting, drilling, and milling operations, making it a versatile choice for a wide array of applications. Whether you’re dealing with metals, plastics, or composites, CNC machining is ideal for achieving consistent results across different materials. Additionally, the ability to automate and repeat machining operations enhances efficiency and reduces the risk of human error. By leveraging the strengths of CNC technology, you can optimize your production process and ensure that your custom parts are manufactured to exact specifications, ultimately leading to superior product quality and customer satisfaction.

3. Key differences: cnc machining vs. sheet metal fabrication

Understanding the key differences between CNC machining and sheet metal fabrication is crucial for making informed decisions about the right process for your application. CNC machining is a subtractive process that involves removing material from a solid block to create intricate and precise parts. This method is particularly advantageous when working with complex geometries and tight tolerances. On the other hand, sheet metal fabrication is often employed for larger, simpler parts and involves bending, cutting, and assembling metal sheets. This fabrication is a manufacturing process that excels in producing cost-effective components with a high degree of versatility. The choice between these two methods largely depends on the specific requirements of your project, including the desired level of detail, material properties, and production volume.

When choosing between CNC machining and sheet metal fabrication, it’s essential to consider the strengths and limitations of each process. CNC machining offers unparalleled precision and is ideal for applications requiring detailed and complex designs. It allows for the production of parts with consistent quality and repeatability, making it a preferred choice for industries that demand high standards. Conversely, sheet metal fabrication depends on the ability to efficiently produce larger quantities of parts with less intricate designs. This method is often more suitable for projects where cost-effectiveness and speed are prioritized. Ultimately, the decision to use CNC machining or sheet metal fabrication should be guided by the specific needs of your project, ensuring that you select the right process for your application to achieve optimal results.

4. How to choose the right process for your cnc machining needs

When determining the most suitable approach for your CNC machining requirements, it’s essential to evaluate the specific demands of your project. CNC machining offers a range of techniques that can be tailored to meet diverse needs, whether you’re focusing on precision, speed, or material properties. Choosing between CNC machining and other methods involves considering factors such as the complexity of the design, the type of material being used, and the desired finish. For projects that require intricate details and tight tolerances, CNC machining is ideal due to its ability to produce consistent and high-quality results. On the other hand, if your project involves larger, simpler parts, sheet metal fabrication excels in providing cost-effective solutions. By understanding the strengths and limitations of each process, you can make informed decisions that align with your objectives, ensuring that your metal components are manufactured to the highest standards. Remember, the right choice not only enhances the quality of your product but also optimizes your production efficiency.

5. Exploring types of cnc machines for precision machining operations

In the realm of precision machining operations, understanding the various types of CNC machines is crucial for optimizing your production strategy. CNC machining offers a diverse range of equipment, each designed to cater to specific manufacturing needs. From CNC mills and lathes to routers and plasma cutters, the choice of machine can significantly impact the quality and efficiency of your operations. Machining involves selecting the right tool for the job, ensuring that you can produce parts with complex geometries and tight tolerances. Whether you’re working with metals, plastics, or composites, the versatility of CNC machines allows for a wide array of applications, making them indispensable in modern manufacturing.

Choosing between CNC machining and other manufacturing methods requires a deep understanding of the capabilities of different CNC machines. Machining provides the precision and repeatability needed for high-quality production, and the ability to remove material with accuracy is a defining feature of CNC technology. CNC machining is a subtractive process, meaning it starts with a solid block of material and removes excess to create the desired shape. This method is particularly advantageous for producing intricate designs and achieving consistent results. By leveraging the strengths of various types of CNC machines, manufacturers can tailor their approach to meet the specific demands of their projects, ensuring that their machining services deliver optimal performance and customer satisfaction.

Exploring the Role of CNC Turning and Milling in Metal Fabrication

In the world of metal fabrication, CNC turning and milling play pivotal roles in producing parts with precision and efficiency. These processes are integral to creating components for a wide range of industries, including aerospace, where precision is paramount. CNC turning involves rotating a piece of material while a cutting tool shapes it into the desired form, making it ideal for producing cylindrical parts. On the other hand, CNC milling uses rotary cutters to remove material from a workpiece, allowing for the creation of complex geometries and intricate designs. Both methods are essential in the fabrication process, offering the ability to work with a range of materials, including metals, to produce parts that meet exact specifications.

When choosing between CNC machining and sheet metal fabrication, it’s important to consider the specific requirements of your project. CNC machining is typically better suited for applications that demand high precision and intricate details, while sheet metal fabrication may be more appropriate for producing larger, simpler parts. The decision often hinges on factors such as production volume, material properties, and the desired finish. By understanding the key differences between these processes, you can select the right approach for your application, ensuring that your custom parts are manufactured to the highest standards. Whether you’re working with flat metal sheets or complex structures, the right choice can significantly impact the quality and efficiency of your production strategy.

FAQs

1. What is the difference between CNC machining and sheet metal fabrication?

The difference between CNC machining and sheet metal fabrication lies in their processes and applications. CNC machining is a subtractive process that involves removing material from a solid block to create precise parts, making it ideal for intricate designs. On the other hand, sheet metal fabrication involves bending, cutting, and assembling sheets of metal, which is typically more suitable for larger, simpler parts. Understanding these key differences helps in choosing the right process for your application.

2. How does CNC turning contribute to metal fabrication?

CNC turning plays a crucial role in metal fabrication by rotating a piece of material while a cutting tool shapes it into the desired form. This process is particularly useful for producing cylindrical parts and is widely used in industries that require precision, such as aerospace. CNC turning, along with CNC milling, forms the backbone of machining operations, allowing for the creation of custom parts with exact specifications.

3. What are the advantages of using CNC milling in fabrication?

CNC milling offers several advantages in fabrication, including the ability to create complex geometries and intricate designs. This process involves using rotary cutters to remove material from a workpiece, making it suitable for a wide range of materials. CNC milling provides precision and repeatability, ensuring that parts and structures meet high-quality standards. It is an essential component of machining services, especially when working with custom parts.

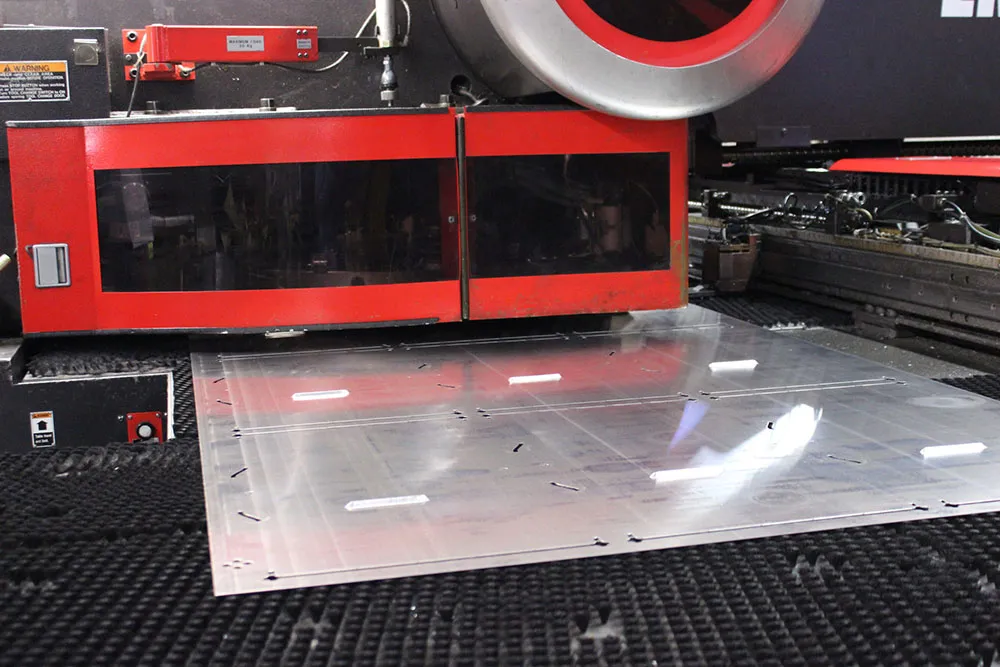

4. Why is laser cutting important in sheet metal fabrication?

Laser cutting is a vital process in sheet metal fabrication as it allows for precise and clean cuts on thin metal sheets. This technique is particularly advantageous when dealing with intricate designs and tight tolerances. Laser cutting enhances the efficiency of fabrication operations, making it a preferred choice for producing sheet metal parts with high precision. It complements other processes like welding and stamping in creating custom metal components.

5. How do you choose the right process for your custom parts?

Choosing the right process for your custom parts involves evaluating the specific requirements of your project, such as production volume, material properties, and desired finish. CNC machining is typically better suited for applications that demand high precision and intricate details, while sheet metal fabrication may be more appropriate for larger, simpler parts. By understanding the strengths and limitations of each process, you can make informed decisions that align with your objectives, ensuring optimal results for your custom parts.