Top 7 Key Factors to Consider When Choosing a Custom CNC Machining Manufacturer in China

When selecting a CNC machine or a parts manufacturer, especially in the realm of custom metal parts, there are several key considerations to keep in mind. Understanding the factors to consider when choosing a CNC machining service, such as OEM capabilities and supplier reliability, is crucial. This guide will explore the key factors to consider when designing and choosing a CNC machining manufacturer, ensuring you make an informed decision for your custom parts needs.

In a recent development, the global demand for precision-engineered metal components has surged, highlighting the critical role of custom CNC machining manufacturers in China. As businesses increasingly seek reliable partners to produce high-quality custom parts, understanding the nuances of selecting the right manufacturer becomes paramount. This article delves into the essential factors that should guide your decision-making process, from evaluating a manufacturer’s capabilities and ensuring robust quality control measures to optimizing design processes for custom metal parts. Additionally, it will address the importance of rapid prototyping and timely delivery solutions, as well as navigating the complexities of lead time and supply chain management in the metal part manufacturing industry. By offering expert insights and practical advice, this guide aims to equip you with the knowledge needed to make informed choices, ensuring your custom CNC machining needs are met with precision and efficiency.

Key considerations for choosing the right cnc machine manufacturer

When it comes to choosing the right CNC machining manufacturer, one of the most important factors is the manufacturer’s ability to provide customized solutions without compromising quality. A critical factor to consider is the manufacturer’s track record in delivering precision CNC machining services that meet your specific requirements. It’s essential to evaluate their expertise in handling complex projects and their commitment to continuous improvement in their manufacturing processes. This ensures that the manufacturer can adapt to evolving industry standards and technological advancements, ultimately enhancing the quality and efficiency of the parts produced.

Another vital aspect to consider when selecting a CNC machining manufacturer is their quality management system. A robust quality management framework is crucial for maintaining high standards and ensuring that the final products meet the desired specifications. Assessing the manufacturer’s certifications, such as ISO standards, can provide insights into their commitment to quality. Additionally, the manufacturer’s ability to meet tight deadlines and manage supply chain complexities is a significant factor to consider when choosing a CNC machining partner. By prioritizing these considerations, you can ensure a successful partnership that delivers high-quality, precision-engineered components tailored to your needs.

Factors to consider when designing custom metal parts

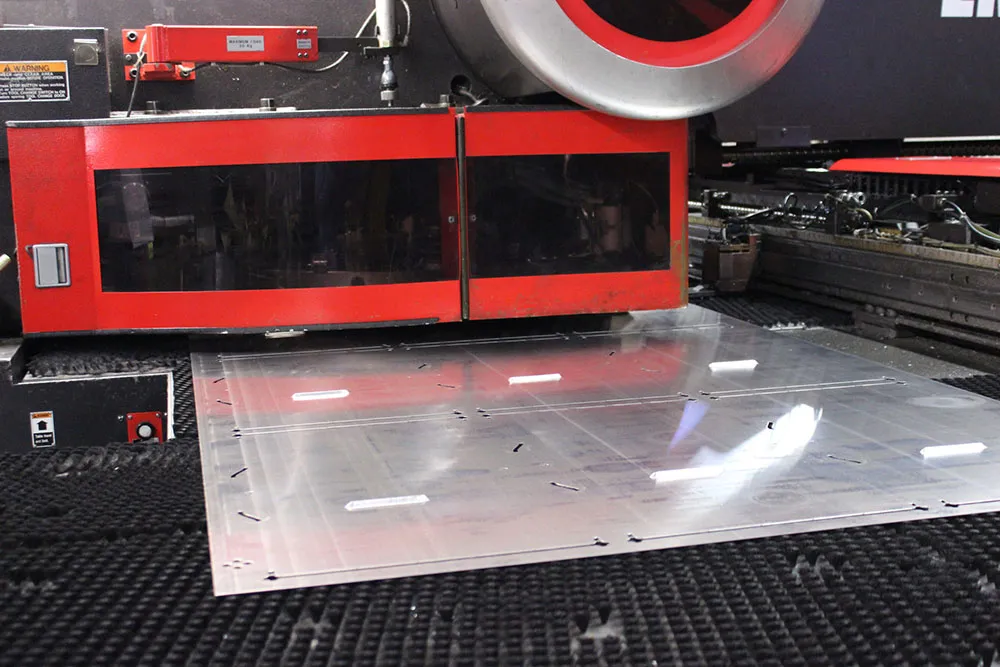

Designing custom metal parts requires a strategic approach that balances functionality, aesthetics, and manufacturability. One of the primary considerations is the selection of materials, as this directly impacts the durability and performance of the final product. Collaborating with a CNC machining manufacturer that offers a wide range of material options can significantly enhance the design process. Additionally, leveraging advanced CNC machines and precision CNC machining techniques ensures that the intricate details of your design are accurately reproduced. It’s crucial to work closely with a CNC machining supplier that prioritizes a robust quality control system to maintain consistency and precision throughout the production cycle. By focusing on these factors, you can optimize the design of your CNC machined parts to meet specific requirements and achieve superior performance.

3. How to ensure quality control in custom cnc machining services

Ensuring quality control in custom CNC machining services is paramount to achieving high standards and precision in the final product. A comprehensive approach involves implementing a robust quality management system that aligns with industry standards such as ISO 9001. This framework should encompass regular audits, detailed inspections, and continuous monitoring of the production process. Collaborating with a CNC machining manufacturer that prioritizes quality control is essential. They should utilize advanced CNC machines and employ skilled technicians to oversee the production of precision CNC machining parts. Additionally, leveraging [object Object] can enhance the accuracy and consistency of the manufacturing process. By focusing on these critical aspects, you can ensure that your CNC machined parts meet the desired specifications and deliver exceptional performance.

4. Top 7 solutions for rapid prototyping and timely delivery

In the fast-paced world of precision CNC machining, ensuring rapid prototyping and timely delivery is crucial for maintaining a competitive edge. Collaborating with a CNC machining manufacturer that offers advanced CNC machines, including 5-axis CNC technology, can significantly expedite the prototyping process. These machines provide enhanced capabilities for producing complex geometries with high precision, reducing the time required for iterations and adjustments. Additionally, a manufacturer in China with a well-established supply chain network can streamline logistics, ensuring that CNC machined parts are delivered promptly to meet project deadlines. By leveraging these solutions, businesses can achieve faster turnaround times without compromising on quality.

Another critical aspect of achieving timely delivery is the implementation of a robust quality management system that aligns with ISO 9001 standards. This ensures that each stage of the production process is meticulously monitored, minimizing errors and rework. A CNC machining supplier that prioritizes efficiency and precision can offer tailored solutions to meet specific project requirements. Furthermore, utilizing [object Object] can enhance the coordination between design and manufacturing teams, facilitating seamless communication and reducing lead times. By focusing on these strategies, businesses can optimize their operations, ensuring that CNC machining parts services are delivered on schedule and to the highest standards.

5. Understanding lead time and supply chain in metal part manufacturing

Efficient management of lead time and the supply chain is crucial in the realm of metal part manufacturing. A well-structured supply chain ensures that CNC machining manufacturers can deliver quality parts on time, meeting the demands of industries that rely on precision CNC machining. The ability to anticipate potential disruptions and proactively address them is a hallmark of a reliable manufacturer in China. By leveraging [object Object], manufacturers can enhance their logistical capabilities, ensuring that CNC machined parts are produced and delivered efficiently. This strategic approach not only reduces lead times but also optimizes the entire production process, from sheet metal fabrication to the final assembly of complex parts.

Incorporating advanced CNC machines and technologies such as CNC milling plays a pivotal role in minimizing lead times and streamlining the supply chain. These technologies enable manufacturers to achieve tight tolerances and facilitate mass production without compromising on quality. A robust supply chain, supported by a comprehensive quality management system, ensures that each component meets the highest standards, ultimately enhancing the reliability of CNC machining parts services. By focusing on these critical elements, businesses can maintain a competitive edge in the market, delivering superior products that meet the evolving needs of their clients.

Choosing the Right CNC Machining Manufacturer: Key Considerations

When it comes to choosing a CNC machining manufacturer, it’s essential to consider several critical factors to ensure you select the right partner for your specific needs. One of the primary considerations is the manufacturer’s expertise in utilizing advanced CNC machines, such as 5-axis CNC and CNC milling technology. These machines are crucial for achieving precision CNC machining, allowing for intricate designs and tight tolerances. Additionally, evaluating the manufacturer’s capabilities in computer-aided design (CAD) and their ability to integrate OEM solutions can significantly impact the quality and efficiency of the production process. By focusing on these aspects, you can ensure that the manufacturer provides tailored solutions that align with your project requirements.

Another vital factor to consider when choosing a CNC machining manufacturer is their commitment to quality and certification standards. A manufacturer that adheres to ISO 9001 and other relevant certifications demonstrates a strong dedication to maintaining high-quality management systems. This commitment ensures that the CNC machined parts produced meet the desired specifications and industry standards. Furthermore, assessing the manufacturer’s customer support and their ability to offer timely delivery solutions is crucial for maintaining a seamless production process. By considering these key factors, you can choose a manufacturer that not only meets your specific needs but also delivers exceptional results in custom CNC machining services.

FAQs

1. What are the key factors to consider when choosing a CNC machining manufacturer?

When choosing a CNC machining manufacturer, consider the following: the manufacturer’s expertise in advanced CNC machines, their ability to provide OEM solutions, and their adherence to ISO 9001 certification. These factors ensure precision CNC machining and high-quality production. Additionally, evaluate their capabilities in CAD design and their experience with various materials, such as alloys, to ensure the best fit for your specific needs.

2. How does ISO 9001 certification impact CNC machining services?

ISO 9001 certification is crucial for CNC machining services as it demonstrates the manufacturer’s commitment to maintaining high-quality management systems. This certification ensures that the CNC machined parts meet industry standards and desired specifications. A manufacturer with ISO 9001 certification is more likely to deliver consistent quality and reliability in their services.

3. What role does CAD play in custom CNC machining?

CAD (Computer-Aided Design) plays a vital role in custom CNC machining by allowing manufacturers to create precise and intricate designs. It facilitates the integration of OEM solutions and ensures that the final product meets specific requirements. CAD also enhances the efficiency of the production process, enabling manufacturers to deliver high-quality CNC machined parts with tight tolerances.

4. Why is rapid prototyping important in CNC machining?

Rapid prototyping is essential in CNC machining as it allows for quick iterations and adjustments, reducing lead time and ensuring timely delivery. By utilizing advanced CNC machines, such as 5-axis CNC technology, manufacturers can produce complex geometries with high precision. This capability is crucial for meeting project deadlines and maintaining a competitive edge in the market.

5. How do global manufacturers ensure quality in CNC machining parts services?

Global manufacturers ensure quality in CNC machining parts services by implementing robust quality control measures and adhering to international standards, such as ISO 9001. They utilize advanced CNC machines and cutting-edge technologies, such as laser cutting and CNC milling, to achieve precision and consistency. Additionally, they focus on continuous improvement and efficient supply chain management to deliver high-quality parts on time.