Discover our expert sheet metal fabrication services, offering custom solutions for all your sheet metal manufacturing needs. From designing to producing high-quality sheet metal parts, our comprehensive service ensures precision and durability. Whether you require custom sheet metal fabrication or a detailed sheet metal fabrication design guide, our team is here to assist you with every aspect of your project.

In the ever-evolving landscape of manufacturing, precision and customization are paramount, especially when it comes to crafting metal parts. Our custom sheet metal fabrication services stand at the forefront of this industry, offering unparalleled expertise in transforming raw metal into meticulously designed components. By leveraging cutting-edge techniques such as laser cutting, we revolutionize the fabrication process, ensuring each piece meets exact specifications with unmatched accuracy. Our comprehensive approach not only covers the intricacies of material selection and finishing but also enhances manufacturing capabilities through advanced methodologies. Whether you’re seeking unique designs or robust solutions, our services are tailored to meet the diverse needs of modern manufacturing, providing both precision and durability in every project.

1. Understanding the advantages of precision sheet metal fabrication

Precision sheet metal fabrication offers a multitude of advantages that are crucial for modern manufacturing. Custom sheet metal parts are crafted with exceptional accuracy, ensuring that each component fits perfectly within its intended application. This level of precision not only enhances the functionality of the final product but also reduces waste and material costs. The sheet metal manufacturing process is highly adaptable, allowing for the creation of complex designs and intricate details that would be challenging to achieve with other materials. Additionally, the versatility of sheet metal fabrication techniques enables the production of both sheet metal prototypes and large-scale production runs, catering to diverse industry needs. By leveraging advanced technologies and methodologies, businesses can achieve superior sheet metal fabrication capabilities, resulting in durable and reliable sheet metal components that meet the highest standards of quality and performance.

2. Exploring custom sheet metal fabrication services for unique designs

In the realm of custom sheet metal parts, the ability to create unique designs is a testament to the versatility and innovation of modern sheet metal services. By utilizing custom online sheet metal fabrication, businesses can access a wide array of design possibilities, enabling the creation of intricate and bespoke components that cater to specific needs. The integration of advanced technologies, such as sheet metal cutting and precision engineering, allows for the development of sheet metal fabricated parts that not only meet but exceed industry standards. This approach ensures that each project is tailored to the client’s specifications, providing a level of customization that is unparalleled in the manufacturing sector.

Moreover, the collaboration with experienced sheet metal manufacturers enhances the potential for innovation in sheet metal design. These experts bring a wealth of knowledge in selecting the appropriate sheet metal fabrication materials, ensuring that the final product is both durable and functional. The sheet metal fabrication process is meticulously planned and executed, taking into account the unique requirements of each project. This attention to detail is crucial in producing sheet metal enclosures and other components that require precision and reliability. By embracing the advantages of sheet metal fabrication, businesses can achieve exceptional results, transforming raw materials into expertly crafted parts that stand the test of time.

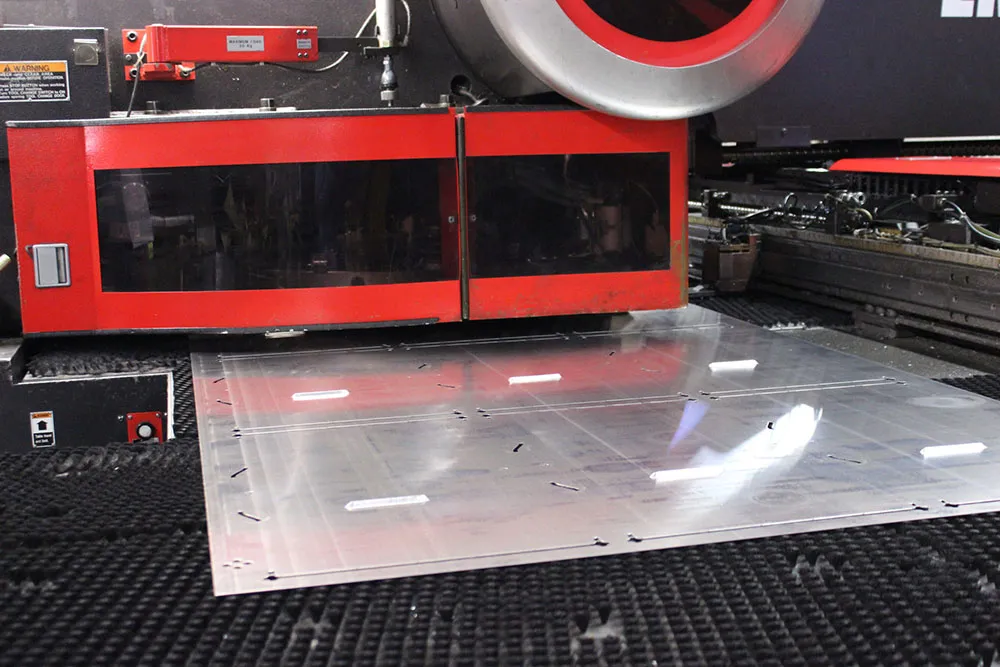

3. Laser cut sheet metal: revolutionizing the fabrication process

Embracing the laser cut sheet metal technique has significantly transformed the landscape of sheet metal fabrication work. This cutting-edge method offers unparalleled precision of sheet metal, allowing for the creation of intricate designs and complex geometries that were once deemed challenging. By utilizing advanced cutting process technologies, manufacturers can achieve exceptional accuracy, ensuring that each component aligns perfectly with the intended design specifications. The ability to work with a variety of sheet metal materials further enhances the versatility of this approach, catering to diverse industry needs and applications. As a result, businesses can produce high-quality thin metal sheets and components with remarkable efficiency, setting new standards in metal fabrication.

The integration of laser technology into fabrication work not only streamlines the production process but also opens up new possibilities for designing sheet metal parts. By precisely cutting and shaping metal forming elements, manufacturers can create bespoke components that meet specific client requirements. This level of customization is crucial in industries where precision and reliability are paramount. Additionally, the ability to incorporate sheet metal finishes and joining sheet metal techniques further enhances the functionality and aesthetic appeal of the final product. Whether it’s creating intricate holes in sheet metal or ensuring seamless assembly, laser cutting stands as a cornerstone of modern metal fabrication. By leveraging these advancements, businesses can achieve superior results, transforming raw materials into expertly crafted components that excel in both performance and durability.

4. Comprehensive guide to sheet metal fabrication materials and finishes

In the realm of sheet metal fabrication, selecting the appropriate sheet metal fabrication materials is a critical step that significantly impacts the quality and functionality of the final product. The choice of material, whether it be stainless steel sheet metal, aluminum, or other various sheet metal types, dictates the durability, weight, and corrosion resistance of the flat sheet metal parts. Each material brings its unique properties to the table, influencing the metal fabrication process and the techniques employed, such as metal bending techniques and the sheet metal stamping process. Understanding these nuances is essential for designing sheet metal parts that meet specific industry standards and client requirements. Collaborating with an experienced sheet metal fabricator can provide invaluable insights into material selection, ensuring that the most suitable options are chosen for each project.

Beyond material selection, the application of sheet metal finishes plays a pivotal role in enhancing both the aesthetic and functional aspects of creating sheet metal parts. Finishes such as powder coating, anodizing, and plating not only improve the appearance of the thin sheets of metal but also add an extra layer of protection against environmental factors. This is particularly important in industries where using sheet metal involves exposure to harsh conditions. The right finish can extend the lifespan of the components, making them more resilient and reliable. By integrating advanced finishing techniques into the manufacturing services for sheet metal, businesses can achieve superior results, ensuring that each piece not only meets but exceeds expectations in terms of performance and longevity.

5. Enhancing manufacturing capabilities with advanced sheet metal techniques

Incorporating advanced sheet metal techniques into the metal fabrication process significantly boosts manufacturing capabilities, enabling businesses to design sheet metal parts with greater precision and efficiency. By leveraging technologies such as CNC machining and mechanical forming, manufacturers can achieve intricate bends in sheet metal and precise corners of sheet metal, ensuring that each component meets exact specifications. The ability to form sheet metal with such accuracy not only enhances the quality of the final product but also optimizes production workflows. As sheet metal is placed and sheet metal is fed through state-of-the-art machinery, the potential for innovation and customization expands, offering a competitive edge in the market. With a wide range of materials available for sheet metal fabrication, and techniques used for sheet metal processing, businesses can source from a reliable supplier or wholesale provider to meet diverse industry demands. This strategic integration of advanced methodologies ensures that the manufacturing process remains at the forefront of technological advancement, delivering superior results and setting new standards in the industry.

Innovative Approaches in CNC and Turning for Sheet Metals

In the realm of modern manufacturing, the integration of CNC technology and turning processes has revolutionized the way we work with sheet metals. These advanced methodologies allow for the precise manipulation of each piece of sheet metal, ensuring that every cut and contour is executed with unparalleled accuracy. By employing CNC machines, manufacturers can automate the fabrication process, reducing human error and increasing efficiency. This not only enhances the quality of the final product but also streamlines production timelines, making it possible to meet tight deadlines without compromising on precision. The ability to execute intricate designs with CNC technology opens up new possibilities for innovation in sheet metal fabrication, catering to the ever-evolving demands of various industries.

Furthermore, the use of turning techniques in conjunction with CNC machinery provides an additional layer of versatility in metal fabrication. This combination allows for the creation of complex geometries and detailed features that are essential in producing high-quality sheet metal parts. As metal is one of the most versatile materials, the ability to precisely shape and form it using these advanced techniques is invaluable. Whether working with a single sheet of metal or multiple components, the integration of CNC and turning ensures that each element is crafted to perfection. This approach not only enhances the sheet metal fabrication process but also sets new standards in the industry, showcasing the potential of technology-driven manufacturing solutions.

FAQs on CNC, Laser, and Mill in Sheet Metal Fabrication

1. What role does CNC play in sheet metal fabrication?

CNC, or Computer Numerical Control, is integral to sheet metal fabrication as it automates the cutting and shaping processes. By using CNC machines, manufacturers can achieve high precision and consistency in creating sheet metal parts. This technology allows for intricate designs and complex geometries to be executed with minimal human error, enhancing the overall quality and efficiency of the manufacturing process.

2. How does laser technology enhance sheet metal fabrication?

Laser technology revolutionizes sheet metal fabrication by providing unparalleled precision in cutting and engraving. The use of lasers allows for clean, accurate cuts on various sheet metal materials, reducing waste and improving the speed of production. This method is particularly beneficial for creating detailed and intricate designs, making it a preferred choice in custom sheet metal fabrication services.

3. What is the significance of milling in metal fabrication?

Milling is a crucial process in metal fabrication that involves removing material from a workpiece to achieve the desired shape and size. In sheet metal fabrication, milling is used to create precise features and finishes on metal parts. This process complements other techniques like CNC and laser cutting, ensuring that each sheet metal part meets exact specifications and quality standards.

4. How does the integration of CNC, laser, and mill improve sheet metal fabrication capabilities?

The integration of CNC, laser, and mill technologies significantly enhances sheet metal fabrication capabilities by combining precision, speed, and versatility. CNC provides automated control, laser offers precise cutting, and milling ensures detailed finishing. Together, these technologies streamline the fabrication process, allowing for the efficient production of high-quality sheet metal parts tailored to specific requirements.

5. What are the advantages of using CNC, laser, and mill in custom sheet metal fabrication services?

Using CNC, laser, and mill in custom sheet metal fabrication services offers several advantages, including increased precision, reduced production time, and the ability to create complex designs. These technologies enable manufacturers to produce custom sheet metal parts with high accuracy and consistency, meeting diverse industry needs. Additionally, they enhance the overall efficiency and cost-effectiveness of the fabrication process, providing superior results for clients.