As a team that spends our days bending, cutting, and shaping sheet metal into all sorts of custom parts, we get asked a lot about the best ways to manufacture things. And honestly, for a huge range of applications, sheet metal stamping comes out on top time and time again.

Think about it – from the brackets holding your car parts together to the enclosures protecting sensitive electronics, chances are a lot of those components were made using sheet metal stamping. It’s a workhorse of a manufacturing process, and today, we want to break down exactly why it’s so advantageous, especially when you’re looking for high volumes of precise, durable parts.

What Exactly is Sheet Metal Stamping?

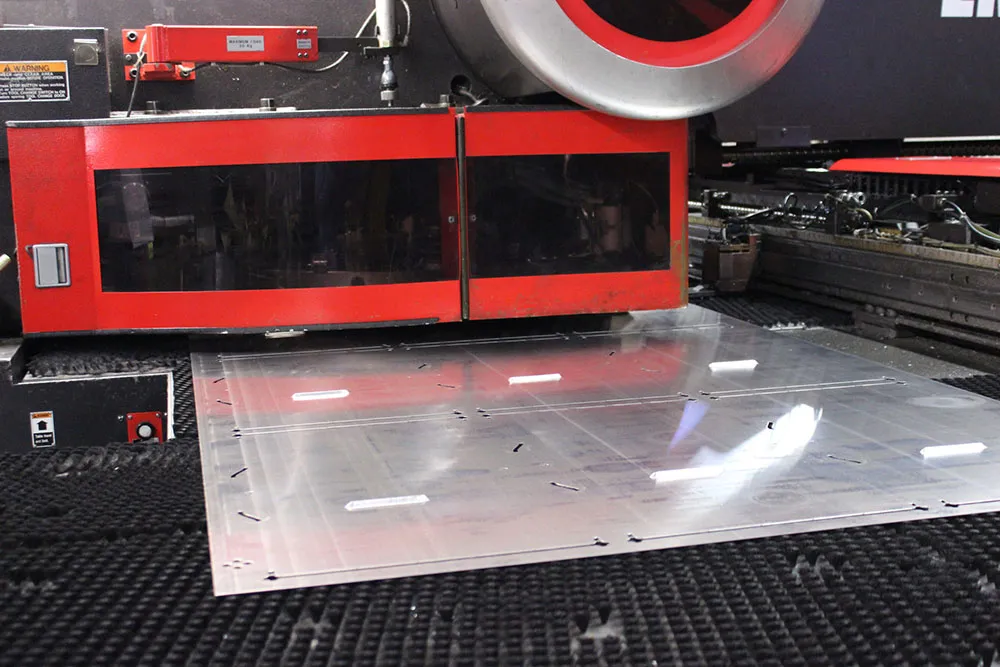

Before we dive into the benefits, let’s quickly recap what sheet metal stamping actually is. Imagine taking a flat sheet of metal (think steel, aluminum, copper, you name it) and using a powerful press and a specialized tool called a die to shape it. This die is like a custom mold designed to create the exact form you need. With a single stroke of the press, you can cut, bend, punch holes, and form complex shapes in the metal. It’s a pretty efficient and precise way to transform raw material into finished parts.

The Big Wins: Why Sheet Metal Stamping Reigns Supreme

Now, let’s get to the good stuff – the advantages that make sheet metal stamping such a compelling choice:

- High-Volume Production at Speed: This is where stamping truly shines. Once the initial tooling (the die) is created, you can churn out a massive number of identical parts incredibly quickly. The cycle times are often just seconds, making it ideal for large production runs where speed and efficiency are paramount. For businesses needing thousands, even millions, of parts, stamping offers a cost-effective solution by scaling production.

- Consistent Quality and Precision: Because the shape is determined by the precise design of the die, every single stamped part will be virtually identical. This consistency in dimensions and form is crucial for assemblies and ensuring the final product functions correctly. Modern stamping processes, especially with advanced CNC-controlled presses, offer tight tolerances and high accuracy that are difficult to achieve with other methods at similar volumes.

- Cost-Effectiveness for Large Runs: While the initial investment in tooling (the die) can be significant, the cost per part drops dramatically as production volume increases. The speed of the process, minimal material waste (especially with progressive dies that perform multiple operations in one go), and reduced labor costs contribute to significant economies of scale. For high-volume needs, stamping often proves to be the most economical manufacturing method.

- Material Versatility: Sheet metal stamping isn’t limited to just one type of metal. We work with a wide array of materials, including various grades of steel (carbon steel, stainless steel), aluminum alloys, copper, brass, and more. This versatility allows you to choose the material that best suits the specific requirements of your part, whether it’s strength, corrosion resistance, conductivity, or weight.

- Complex Shapes and Features: Don’t let the idea of “stamping” fool you into thinking it’s only for simple, flat parts. Modern stamping techniques, especially progressive die stamping, can create surprisingly intricate geometries and features. We can incorporate bends, flanges, ribs, embossments, and even threaded holes directly into the stamping process, reducing the need for secondary operations and further streamlining production.

- Excellent Strength and Durability: Parts formed through stamping often exhibit excellent strength and durability. The cold working process involved in stamping can actually increase the material’s hardness and tensile strength. This makes stamped parts reliable and long-lasting in various applications.

- Reduced Material Waste: Advanced stamping techniques, particularly progressive die stamping, are designed to optimize material usage. By carefully planning the layout of parts on the metal sheet, we can minimize scrap and make the most efficient use of raw materials, contributing to cost savings and environmental responsibility.

View Well: Your Trusted Partner for Custom Sheet Metal Stamping

At View Well, we’re not just manufacturers and suppliers; we’re your partners in bringing your designs to life. We understand the critical role that high-quality, precisely manufactured sheet metal parts play in your products. That’s why we’ve invested in state-of-the-art equipment and a team of experienced engineers and technicians dedicated to delivering excellence.

Whether you need intricate components for your CNC machinery, robust enclosures for your electronic devices, or custom brackets for your industrial applications, we have the expertise and capabilities to meet your specific requirements. We pride ourselves on:

- Custom Solutions: We work closely with you from the initial design phase to ensure your parts are manufactured to your exact specifications.

- Quality Assurance: Our rigorous quality control processes guarantee that every part we produce meets the highest standards of accuracy and durability.

- Competitive Pricing: We offer cost-effective solutions, especially for medium to high-volume production runs.

- Material Expertise: We can guide you in selecting the optimal material for your application based on performance, cost, and environmental considerations.

- Timely Delivery: We understand the importance of meeting deadlines and are committed to delivering your parts on time.

Looking for a Reliable Partner? Let’s Talk!

If you’re involved in CNC manufacturing or require a dependable supplier for your sheet metal components, View Well is here to help. We are passionate about what we do and are eager to forge strong, long-term business partnerships.

Ready to experience the advantages of professionally manufactured sheet metal stamping parts?

Contact us today for a consultation and lets discuss how we can support your needs for CNC, sheet metal manufacturing, and supply services. We’re confident that our expertise and commitment to quality will make us your preferred partner.