Welcome to work with your Best Suitable Manufacturer & Get your

Custom Parts Done Right Manufactured.

Discover the difference for faster lead times, higher-quality parts, no minimum order quantities, and extensive capabilities. Partner with View Well for all of your production needs.

- Free Quotation

- No Minimum Order Quantities

- Full Mechanical BOM Capabilities

Welcome to work with your Best Suitable Manufacturer & Get your

Custom Parts Done Right Manufactured.

Discover the difference for faster lead times, higher-quality parts, no minimum order quantities, and extensive capabilities. Partner with View Well for all of your production needs.

- Free Quotation

- No Minimum Order Quantities

- Full Mechanical BOM Capabilities

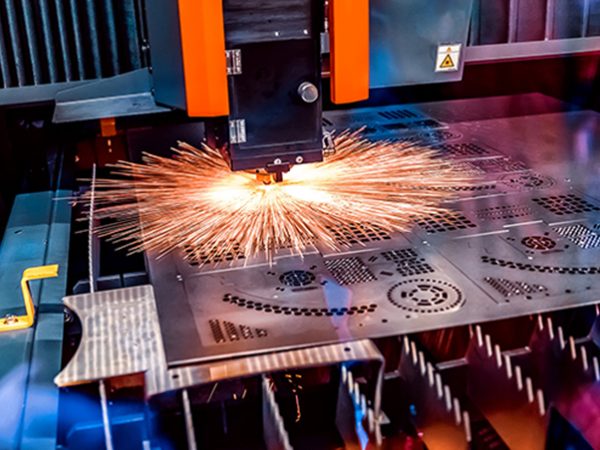

Manufacturing Capacity

From stainless steel,aluminium alloy to titanium alloy,from CNC to Turning Milling composite processing technology,from sandblasting,polishing to PVD and anodic

Production Capacity

CNC machining is commonly used in the automotive industry. All of our services can be leveraged to meet industry trends like autonomous driving, hybrid drive trains, and high-end,

Automotive Accessories

View Well can manufacture Automotive Accessories like Engine Components, Gearbox Parts, Brackets and Mounts, Exhaust Systems, Suspension Components, Wheel Hubs and Rims, Interior Trim Parts, Fuel System Parts, Lighting Components, Body Panels as per customer requirements

Consumer Electronics

View Well can manufacture Consumer Electronics parts like Smart device casings, Wearable Device Components, Audio Equipment, Router and Modem Casings, Gaming Console Parts, Tablet Stands and Mounts, Smart Home Devices parts and accessories as per customer requirements

Industrial Product

View Well can manufacture Industrial parts like Pump Housings, Valve Bodies, Gear Assemblies, Hydraulic Components, Conveyor System Parts, Tooling and Dies, Heat Exchangers, Motor Housings, Machine Frames and Bases, Control Panels According to the customer needs

Telecommunication Parts

View Well can manufacture Telecommunication parts like Antenna Housings, RF Components, Server Racks and Cabinets, Base Station Enclosures, Fiber Optic Connectors, Heat Sinks, Brackets and Mounts, Shielded Enclosures, Patch Panels and Satellite Dish Components according to customer requirements

Medical Parts

View Well can manufacture Medical parts like Medical Device Housings, Prosthetic Parts, Surgical Instruments, Implant Components, Dental Instruments, Diagnostic Equipment Parts as per customer needs

Professional Manufacturing

Highest quality inspection team equipped with Professional inspection instruments

View Well was founded in 2003, specializing in machining, stamping and sheet metal precision parts production services. At present, we have more than 550 employees, including more than 80 engineers and technicians.