Here in this Blog post, i would like to welcome you to all the aspects about exploring the advantages of outsourcing manufacturing over in-house production. Discover the benefits of outsourced manufacturing and learn why you should consider outsourcing the manufacturing of your products. This comprehensive guide will provide insights on how to effectively outsource your manufacturing processes.

In an era where efficiency and cost-effectiveness are paramount, outsourcing manufacturing has emerged as a strategic solution for many businesses. According to recent studies, companies that outsource part of their manufacturing processes can reduce production costs by up to 30%, allowing them to focus on core competencies and innovation. This guide delves into the compelling reasons why outsourcing might be the optimal choice over traditional in-house production. By examining the intricacies of the supply chain, we will explore how outsourcing can seamlessly integrate into your business model, offering substantial cost savings and operational advantages. Additionally, we will discuss the scenarios where offshore manufacturing becomes a viable option, providing insights into making informed decisions that align with your company’s goals. Whether you’re a small business or a large corporation, understanding the benefits of outsourcing manufacturing can be a game-changer in today’s competitive market.

1. Why outsource manufacturing: exploring the core benefits

Embracing manufacturing outsourcing can be a transformative decision for businesses aiming to enhance their operational efficiency. By leveraging the expertise of specialized manufacturing facilities, companies can significantly reduce overhead costs and allocate resources more effectively. This strategic move not only streamlines production but also allows businesses to focus on innovation and core competencies. Moreover, outsourcing manufacturing eliminates the need for substantial capital investment in infrastructure, enabling companies to scale operations swiftly in response to market demands. The flexibility offered by the outsourced manufacturing model is particularly advantageous in today’s dynamic business environment.

Another compelling reason to consider outsourcing is the access it provides to a global talent pool and advanced technologies. Outsourcing manufacturing allows companies to tap into the expertise of seasoned professionals and cutting-edge machinery that might not be available in-house. This not only enhances product quality but also accelerates time-to-market, giving businesses a competitive edge. Additionally, outsourcing manufacturing offers the opportunity to mitigate risks associated with supply chain disruptions by diversifying production locations. As a result, companies can maintain continuity and resilience in their operations, ensuring they remain agile and responsive to changing market conditions.

2. In-house vs. outsourcing production: making the right choice

Determining whether to opt for in-house manufacturing or outsourcing production is a critical decision that can significantly impact a company’s bottom line. While in-house production offers control over the manufacturing process and the ability to maintain close oversight, it often comes with higher manufacturing costs due to the need for substantial investment in a manufacturing facility and workforce. On the other hand, outsourcing, particularly to regions like China, can help reduce costs by leveraging lower cost of labor and accessing advanced technologies through a contract manufacturing organization. However, it’s essential to weigh the pros and cons of outsourcing, such as potential challenges in communication and quality control. Ultimately, the decision should align with the company’s strategic goals, considering factors like the manufacturing and supply chain dynamics, the nature of the product, and the desired level of flexibility in the manufacturing operation.

3. Understanding the supply chain: how manufacturing outsourcing fits in

Incorporating outsourcing manufacturing into the supply chain can be a strategic move for manufacturing companies looking to enhance efficiency and reduce costs. By partnering with specialized manufacturing companies that outsource, businesses can streamline their operations and focus on core competencies. This approach not only allows companies to leverage the expertise and advanced technologies of their partners but also provides flexibility in scaling production according to market demands. For those looking to outsource manufacturing, understanding the intricacies of the supply chain is crucial to ensure a seamless integration and to maximize the benefits of outsourcing.

When deciding to outsource manufacturing, it’s essential to establish a robust outsourcing relationship with your partners. This involves clear communication, setting expectations, and continuously monitoring performance to ensure quality standards are met. For many businesses, outsourcing manufacturing to China has become a popular choice due to the cost advantages and access to a vast network of suppliers. However, it’s important to weigh the reasons to outsource against potential challenges, such as cultural differences and logistical complexities. Ultimately, a well-executed guide to outsource manufacturing can lead to significant operational improvements and a competitive edge in the market.

4. Cost savings and core competencies: the advantages of outsourcing

For many businesses, outsourcing manufacturing makes sense as it allows them to minimize the manufacturing cost while focusing on their core competencies. By choosing to outsource, companies can allocate resources more efficiently, directing their efforts towards innovation and strategic growth rather than getting bogged down in the complexities of production. This strategic decision not only helps in reducing the manufacturing cost of the entire operation but also provides access to advanced technologies and expertise that might not be available in-house. As a result, businesses can reap the benefits of improved product quality and faster time-to-market, giving them a competitive edge in the industry.

When companies consider outsourcing manufacturing, particularly to regions like China, they often find that offshore manufacturing is most suitable for achieving significant cost savings. Outsourcing allows companies to leverage the lower cost of labor and the extensive network of suppliers available in these regions. However, it’s crucial to weigh the risks and benefits of different outsourcing strategies to ensure alignment with the company’s long-term goals. A well-structured guide on how to outsource can help businesses navigate these complexities, ensuring they make informed decisions that maximize the advantages of outsourcing while mitigating potential risks. Ultimately, outsourcing their manufacturing can be a transformative move that enhances operational efficiency and drives business success.

5. Offshore manufacturing: When does outsourcing make sense?

In the ever-evolving manufacturing industry, the decision to embrace offshore manufacturing can be pivotal for businesses aiming to optimize their operations. Outsourcing manufacturing involves collaborating with outsourced manufacturing companies that offer specialized expertise and resources, enabling businesses to produce products at a lower cost. This approach is particularly advantageous for companies looking to reduce overheads associated with maintaining your own manufacturing facility. By strategically selecting the right manufacturing partner, businesses can leverage global capabilities and access advanced technologies that might not be feasible in-house. However, it’s crucial to carefully assess the risks and benefits of different outsourcing strategies to ensure alignment with the company’s long-term objectives.

For many businesses, it makes sense to outsource when aiming to remain competitive in a global market. Outsourcing allows companies to focus on their core competencies while benefiting from the cost efficiencies of outsourcing manufacturing to China or other cost-effective regions. This strategic move not only enhances operational efficiency but also provides the flexibility to scale production in response to market demands. However, the decision to outsource should be made after a thorough evaluation of the benefits of different solutions and the potential challenges associated with outsourcing. By understanding the nuances of offshore manufacturing, businesses can make informed decisions that drive growth and innovation.

6. Custom Solutions and Cost Reduction: The Role of Outsourcing in Product Design

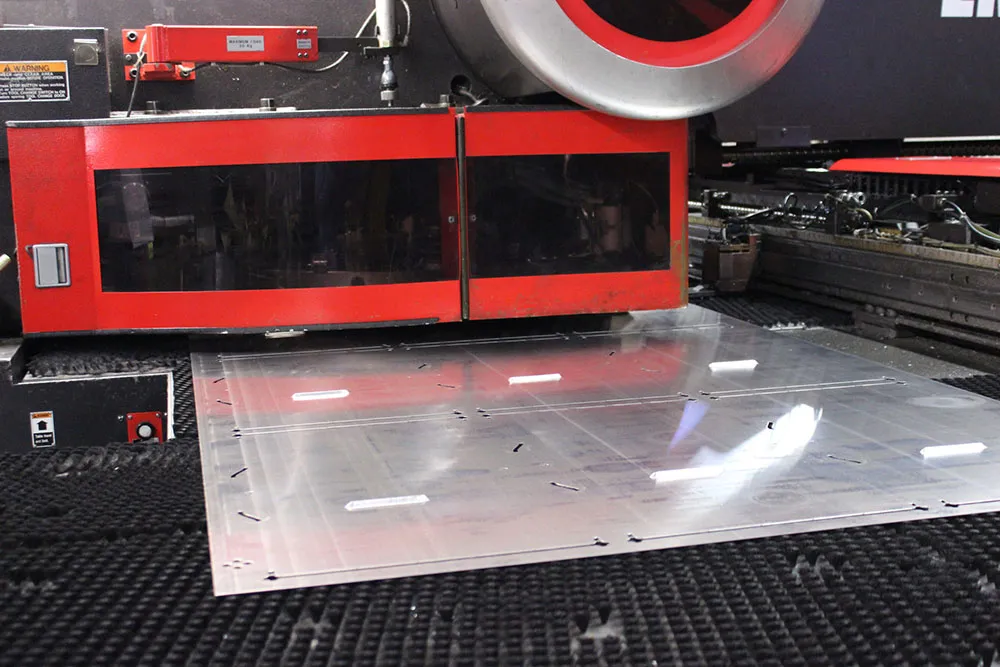

Outsourcing manufacturing is the process that enables companies to achieve significant cost reduction while focusing on custom product design. By partnering with specialized manufacturing companies, businesses can access advanced technologies such as CNC and stamping, which are crucial for creating bespoke products. This approach not only reduces labor costs but also streamlines the production process, allowing companies to save more or have outsource manufacturing at 100% efficiency. The ability to outsource manufacturing makes sense for companies aiming to enhance their product offerings without the need for substantial investments in manufacturing facilities.

Moreover, outsourcing manufacturing involves collaborating with OEMs and wholesale suppliers to optimize the supply chain and manage inventory at different manufacturing locations. This strategic move helps in mitigating the higher manufacturing lead times often associated with in-house production. By leveraging the expertise of manufacturing companies that outsource, businesses can focus on their core competencies and benefit from the advantages of outsourcing, such as cost savings and improved product quality. Ultimately, the decision to consider outsourcing manufacturing is driven by the need to remain competitive in a dynamic market, where custom solutions and efficient production processes are key to success.

FAQs

1. How does outsourcing manufacturing to China impact cost savings?

Outsourcing manufacturing to China can significantly reduce the cost of the entire product due to lower labor costs and access to a vast network of suppliers. This strategic move allows companies to leverage cost efficiencies and focus on core competencies, making it a viable option for businesses aiming to enhance their competitive edge.

2. What role does CNC play in outsourced manufacturing?

CNC, or Computer Numerical Control, is a crucial aspect of outsourced manufacturing that enables companies to achieve precision and efficiency in production. By partnering with specialized manufacturing companies that utilize CNC technology, businesses can enhance product quality and reduce lead times, ultimately benefiting from the advantages of outsourcing.

3. Why might a company consider outsourcing manufacturing?

A company might consider outsourcing manufacturing to focus on innovation and strategic growth while reducing overhead costs. Outsourcing allows companies to access advanced technologies and expertise that might not be available in-house, enabling them to streamline operations and improve product offerings.

4. What are the benefits of partnering with OEMs in manufacturing outsourcing?

Partnering with OEMs (Original Equipment Manufacturers) in manufacturing outsourcing provides businesses with access to specialized expertise and resources. This collaboration helps in optimizing the supply chain, managing inventory efficiently, and ensuring high-quality production, which are essential benefits of outsourcing manufacturing.

5. How does outsourcing manufacturing help in managing the supply chain?

Outsourcing manufacturing involves partnering with experienced manufacturing companies, which helps in managing various aspects of the supply chain. This approach enables companies to reduce lead times, enhance flexibility, and maintain continuity in operations, ensuring they remain agile and responsive to market demands.