Explore the Keys and Benefits of Micro CNC Machining in Modern Manufacturing

Discover how CNC machines, including micro CNC machining and CNC milling techniques, are revolutionizing modern manufacturing practices. Learn about the advantages of using CNC, the key benefits of precision in micro machining, and how these applications improve manufacturing efficiency and quality. Learn about milling machine best practices and applications and how CNC technology is redefining the industry.

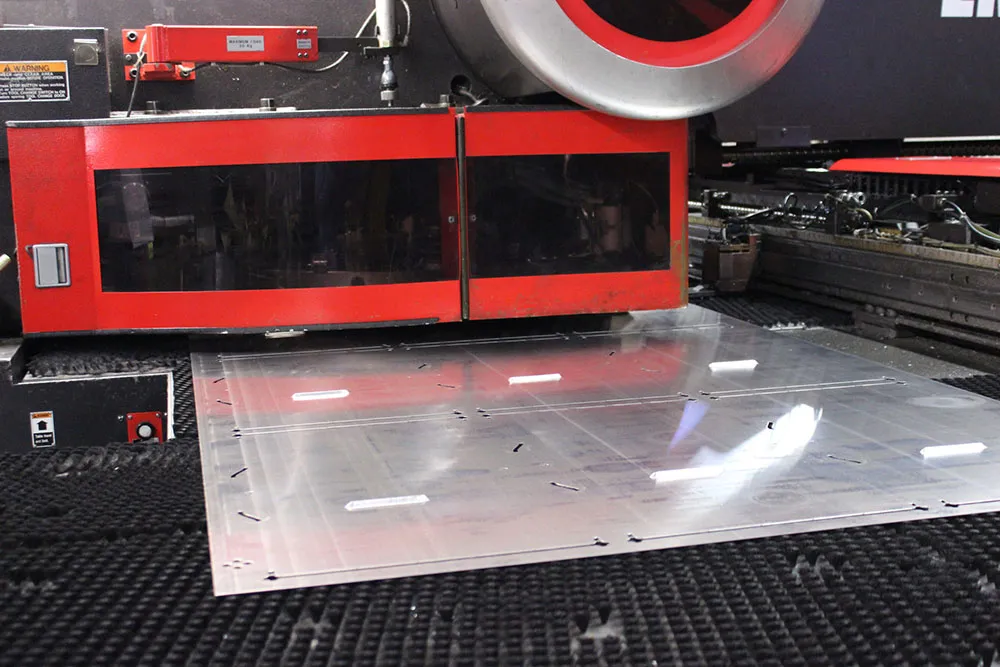

Recently, the manufacturing industry has witnessed significant advancements in the implementation of CNC technology, highlighted by a report on how CNC machines are transforming the production of high-precision components. This article explores how micro CNC machining and CNC milling are redefining efficiency and quality in modern manufacturing. CNC machines, known for their precision and versatility, are revolutionizing the creation of complex parts, allowing manufacturers to achieve unprecedented levels of accuracy. A deeper dive into the applications of micro CNC machining reveals its key benefits, such as the ability to produce tiny parts with extremely tight tolerances, crucial for industries demanding millimeter precision. Additionally, best practices and expert techniques in micro machining will be discussed, providing practical solutions to optimize the use of these advanced tools. With CNC technology at the forefront, machining services are improving precision and accuracy in complex applications, ensuring manufacturers can meet growing market demands with confidence and efficiency.

Exploring the key benefits of CNC machining in modern manufacturing

In modern manufacturing, the implementation of CNC technology has allowed companies to achieve unprecedented levels of precision and efficiency. CNC machining offers the ability to produce complex parts with millimeter accuracy, which is essential for industries requiring high-precision components. CNC machines can produce parts with extremely tight tolerances, which not only improves the quality of the final product but also reduces material waste and optimizes the use of resources. Furthermore, CNC machining ensures greater consistency in production, eliminating human error and ensuring that each part meets the highest quality standards.

The versatility of CNC technology extends across diverse applications, from CNC milling machines to CNC turning, allowing manufacturers to quickly adapt to changing market demands. CNC machining provides a platform for innovation, enabling the creation of complex designs that were previously impossible with traditional methods. Furthermore, CNC machining allows for process automation, which not only increases productivity but also frees up operators to focus on more strategic tasks. With the support of CNC machining services, companies can consistently deliver high-quality products, ensuring their competitiveness in an increasingly demanding global market.

Understanding the Applications of Micro CNC Machining for Precision Parts

In the field of high-precision component manufacturing, Micro CNC Machining has become an indispensable tool. This approach enables the creation of parts with minute details and extremely tight tolerances, which is essential for industries such as aerospace, medical, and electronics. CNC machining offers the ability to produce complex components that meet the strict quality and precision standards required by these sectors. Furthermore, CNC machining provides a platform for innovation, allowing engineers to design and manufacture parts that were previously impossible using conventional methods. The versatility of CNC technology ensures that manufacturers can quickly adapt to changing market demands, maintaining competitiveness and efficiency in their operations.

The applications of Micro CNC Machining are vast and varied, ranging from the production of microcomponents for medical devices to critical parts for the automotive industry. Precision in Micro machining is crucial to ensure that each component functions properly in its final application. CNC machining requires a meticulous approach and attention to detail, ensuring that each part meets exact specifications. CNC Machining ensures that final products are not only accurate but also consistent, reducing the risk of failure and improving product reliability. With the support of CNC Machining Services, companies can Offer consistently high-quality products, securing their place in an increasingly demanding global market.

The advantages of using CNC milling machines for high-precision production

In the competitive world of manufacturing, the use of CNC milling machines has become a standard for achieving high-precision production. CNC machining offers several advantages that are crucial for manufacturers seeking to maintain a superior level of quality. The ability of these machines to produce parts with exceptional precision is one of the main benefits. CNC machining provides the ability to create complex components with minimal tolerances, which is essential for industries that demand micro-precision machining. Furthermore, the precision and accuracy achieved by these machines not only improves the quality of the final product but also optimizes the use of materials, reducing waste and improving operational efficiency.

The integration of CNC technology into the production process allows manufacturers to quickly adapt to market demands, ensuring that each part meets the highest quality standards. CNC milling involves a meticulous approach that guarantees consistency in every production batch. CNC machining ensures that final products are not only precise but also reliable, which is vital for critical applications. The advantages of CNC machining extend to the ability to automate processes, freeing up operators to focus on more strategic tasks. With the support of CNC machined parts, companies can consistently deliver high-quality products, ensuring their competitiveness in an increasingly demanding global market.

- Expert techniques in microprecision machining: best practices and methods

The implementation of expert techniques in microprecision machining is essential to achieving a level of precision that meets the most demanding industry standards. Using appropriate microtools is crucial to ensuring that each component is manufactured with the utmost accuracy. CNC machining provides a robust platform that allows manufacturers to integrate these tools efficiently, ensuring that every step of the production process is optimized for high microprecision. Furthermore, adopting best practices and methods in the use of CNC technology not only improves the quality of the final product but also increases operational efficiency, reducing production time and minimizing material waste.

In sectors such as medical device manufacturing, where micro-precision is critical, expert techniques play a pivotal role in the success of micro-CNC machining. CNC machining ensures that each part meets exacting specifications, which is vital for applications where reliability and consistency are paramount. Collaborating with specialized CNC machining services can provide a competitive advantage, allowing companies to stay ahead in an increasingly demanding global market. By implementing successful micro-CNC practices, manufacturers can consistently deliver high-quality products, ensuring their position as industry leaders.

- How CNC machining services enhance precision and accuracy in complex applications

The integration of CNC machining services into complex applications is critical to achieving a level of precision and accuracy that meets the most rigorous industry standards. CNC machining is known for its ability to handle intricate tasks, allowing manufacturers to produce components with minute details and extremely tight tolerances. CNC technology not only improves the quality of the final product but also optimizes the production process by reducing time and material waste. CNC machining offers a robust platform that ensures consistency and reliability in every part produced, which is crucial for sectors such as aerospace and medical. By collaborating with CNC machining services, companies can take advantage of CNC machining to remain competitive in an increasingly demanding global market, ensuring that each product meets exact specifications and customer expectations.

Exploring the Manufacturing Process: The Importance of CNC Machine Tools

In the world of modern manufacturing, the manufacturing process has evolved significantly thanks to the implementation of CNC machine tools. These machines, which operate under computer numerical control, have revolutionized the way components are produced, especially in critical sectors such as medical device manufacturing. The ability of CNC machines to perform machining operations with an unprecedented level of precision is critical to ensuring the quality and reliability of final products. Unlike manual machines, CNC machines offer consistency and accuracy that are essential in precision-critical applications.

The CNC machining method not only improves the efficiency of the production process but also allows manufacturers to explore new possibilities in the design and creation of complex parts. The importance of CNC machine tools lies in their ability to perform tasks that would be impossible or extremely complicated with traditional machining methods. Furthermore, the use of CNC in medical device manufacturing ensures that each component meets the highest standards of quality and safety. By adopting these advanced technologies, companies can stay competitive and respond effectively to global market demands.

FAQs

- What is the manufacturing process in the context of CNC machines?

The manufacturing process with CNC machines, or computer numerical control, involves the use of automated machine tools to produce components with high precision. Unlike manual machines, CNC machines offer a level of accuracy and consistency that is essential for critical applications, such as medical device manufacturing. This machining method allows manufacturers to explore new possibilities in the design and creation of complex parts. - What are the advantages of CNC machining in modern production?

CNC machining offers numerous advantages in modern production, including the ability to produce parts with an exceptional level of precision. CNC machining ensures that each component meets exact specifications, reducing material waste and optimizing the use of resources. In addition, CNC machining provides greater consistency in production, eliminating human error and ensuring high-quality products. - How do you explain the different types of CNC machines?

There are several types of CNC machines, each designed for specific applications. The most common include CNC milling machines, CNC lathes, and CNC grinding machines. Each type of machine uses different machining methods to produce precision components. CNC machining is compatible with various materials and applications, allowing manufacturers to adapt to changing market demands. - What is the importance of precision in micromachining?

Precision in micromachining is crucial to ensure each component functions properly in its final application. Micromachining requires a meticulous approach and attention to detail, ensuring each part meets exact specifications. CNC precision in micromachining allows for the production of tiny components with extremely tight tolerances, which is essential in sectors such as medical device manufacturing. - What benefits does micromachining offer in modern manufacturing?

Micromachining offers several benefits in modern manufacturing, including the ability to produce complex components with high precision. Micromachining capabilities allow manufacturers to create parts that were previously impossible with traditional machining methods. Furthermore, micromachining reduces material waste and improves operational efficiency, which is crucial for remaining competitive in an increasingly demanding global marketplace.